oneTesla was originally inspired by two things. Firstly, the existence of the FGH60N60SMD IGBT, which uses fairly novel field-stop technology and is significantly faster, cheaper, and bulkier than most other IGBT's on the market. Secondly, I was sick of the failure-prone nature of DRSSTC's - it wasn't bridge failures due to overcurrent that annoyed me, but rather sporadic failures such as loose wires, mechanical strain, and damage during transportation to demos.

The first iteration of oneTesla was designed and laid out over the course of three days in February, backed by copious amounts of bad pop music and caffeine. It used a BNC jack for interrupter input, FGH40N60SMDF IGBT's, a hand-wound current transformer, and couldn't play music.

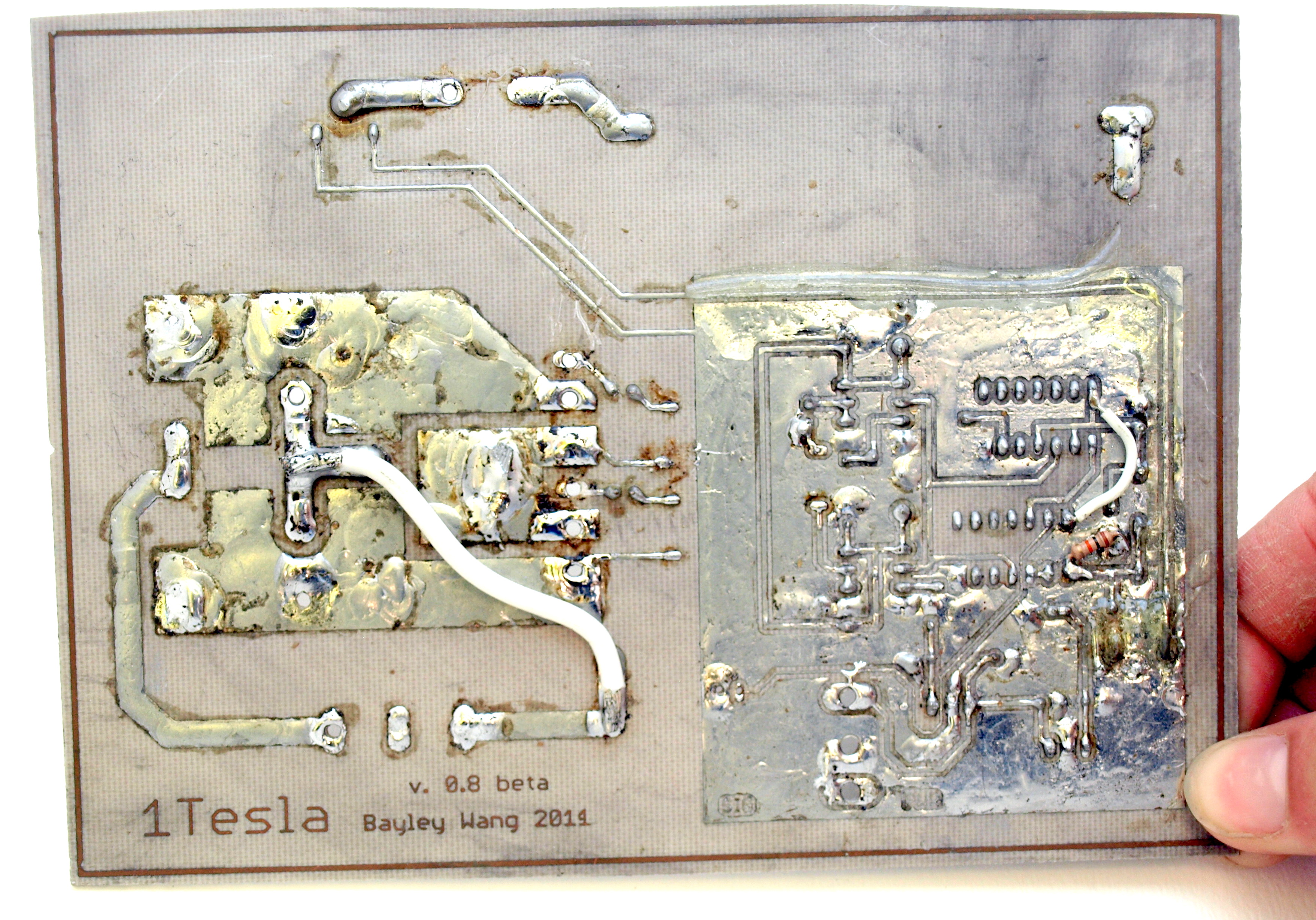

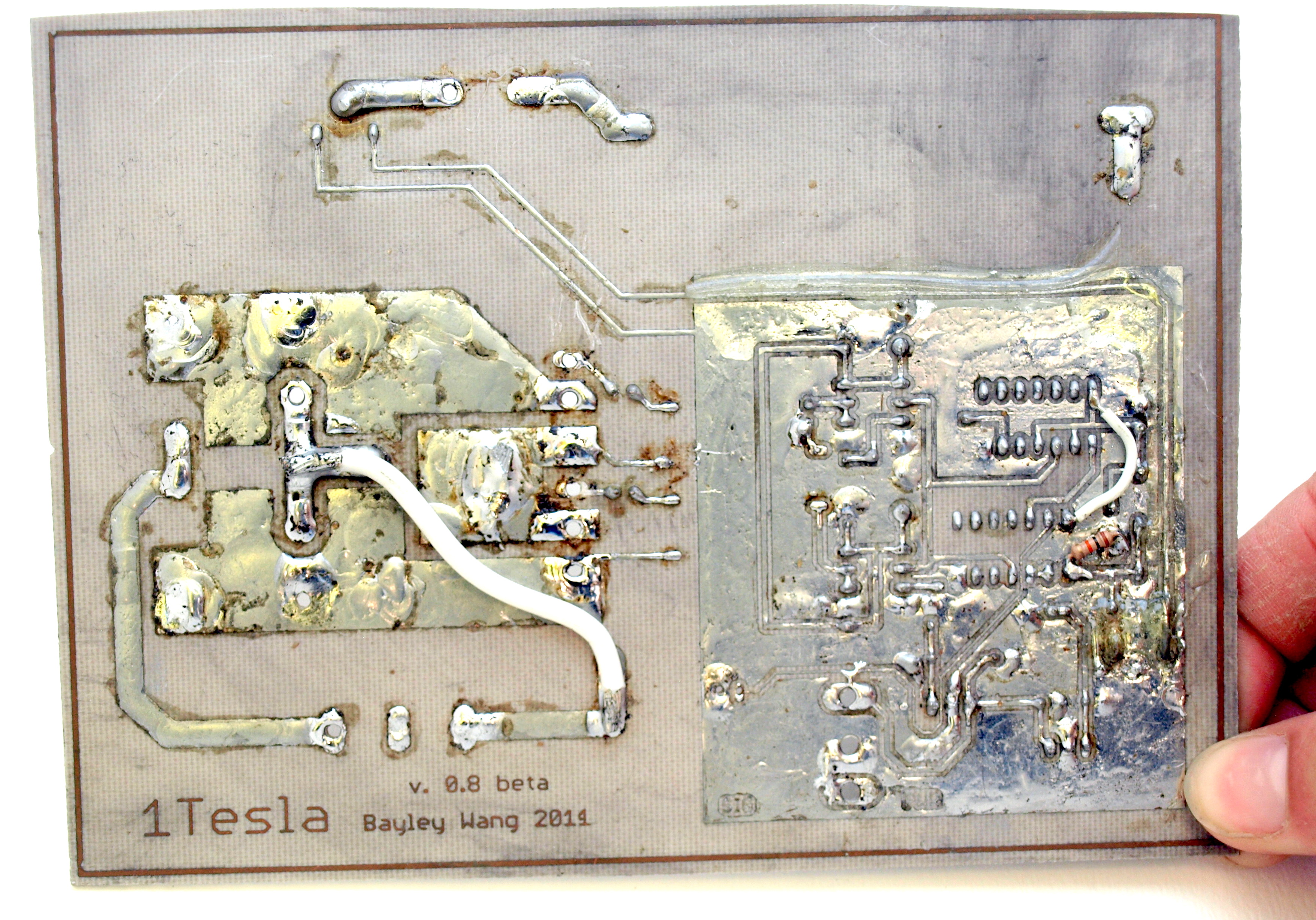

The first (hand-etched) board wasn't tested until mid-April. Version 0.8 suffered from the disastrous problem of not having a high enough CT turns ratio. As soon as the primary current rang up high enough, the feedback CT would force tens of amps through the feedback resistor, burning it up.

Version 0.85 fixed this by sourcing a commercially available 300:1 CT from Triad Magnetics, and also replaced the 1/4W feedback resistor with a 5W wirewound resistor. This fixed the critical flaws of the prior revision, and resulted in a working Tesla coil. The old design paradigm was "efficiency first", which meant running very low duty cycles and pulsewidths, resulting in ~7" long sparks at about 50W into the coil.

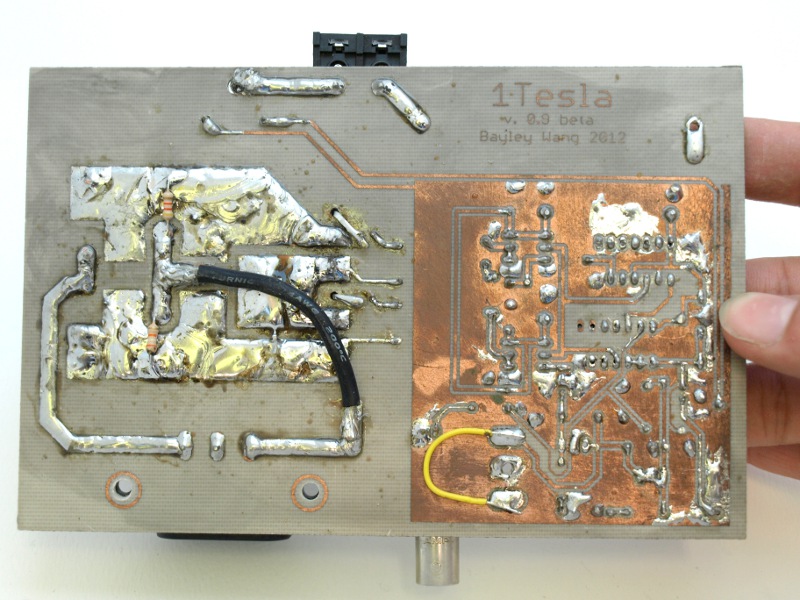

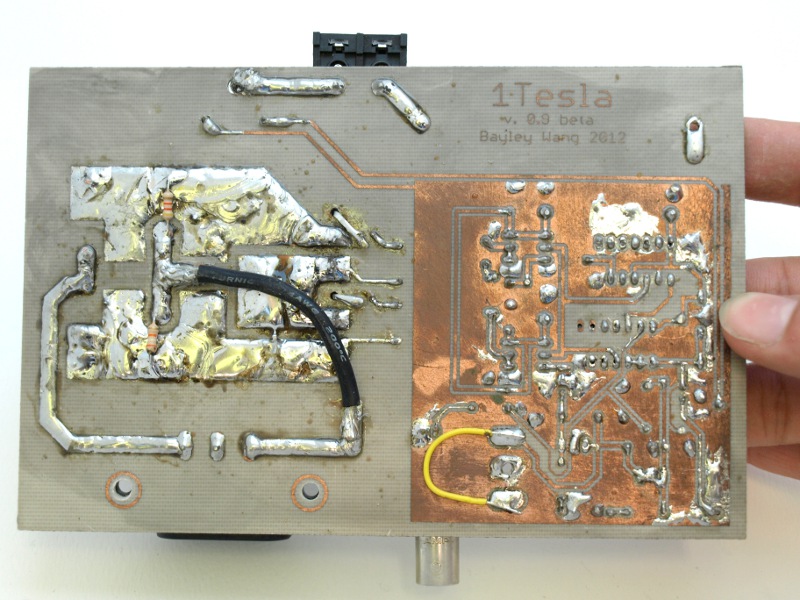

Version 0.9 came next:

At this point, Kramnik re-designed the board to use an optocoupled interrupter, and etched a variant of the coil. This coil was used as a testbed for the development of the firmware that eventually became the oneTesla MIDI controller. At some point, we also realized that grounding the secondary to mains ground was actually more reliable than using a big foil counterpoise, and also significantly improved streamer performance. However, this revision was still somewhat noise-prone.

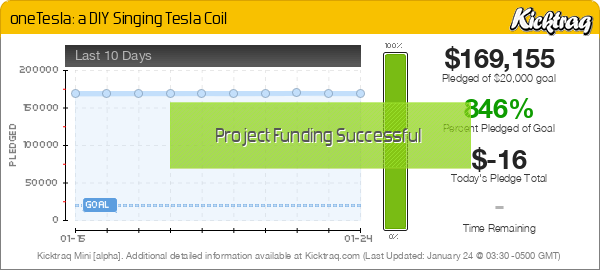

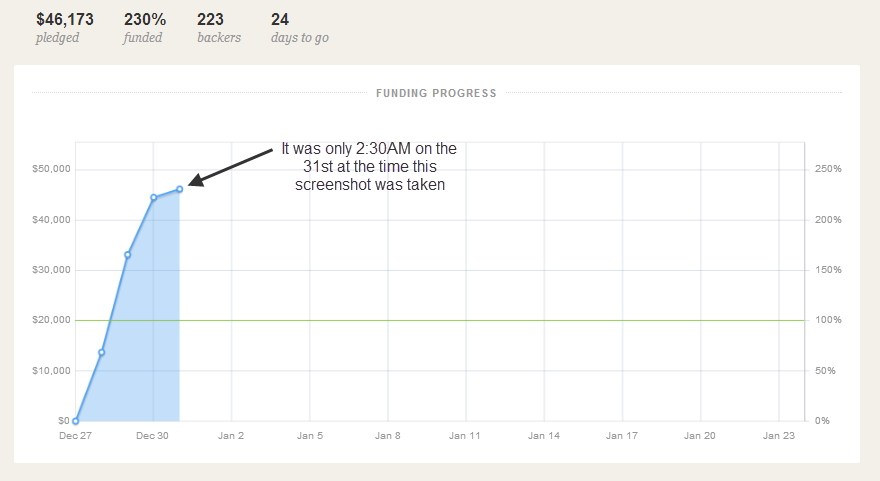

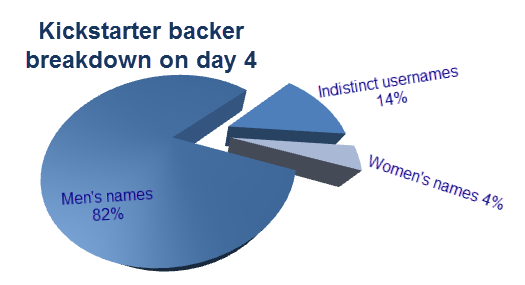

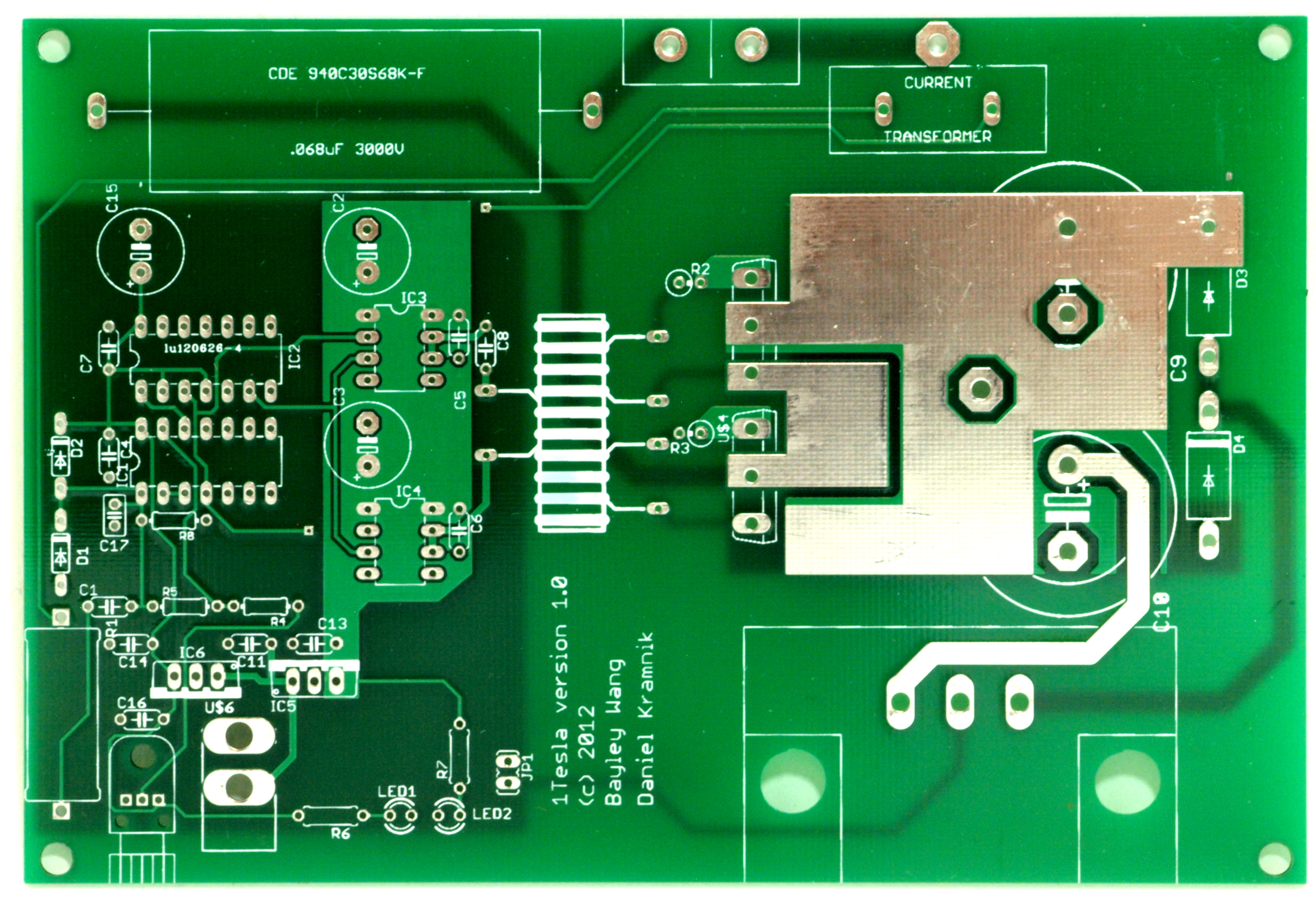

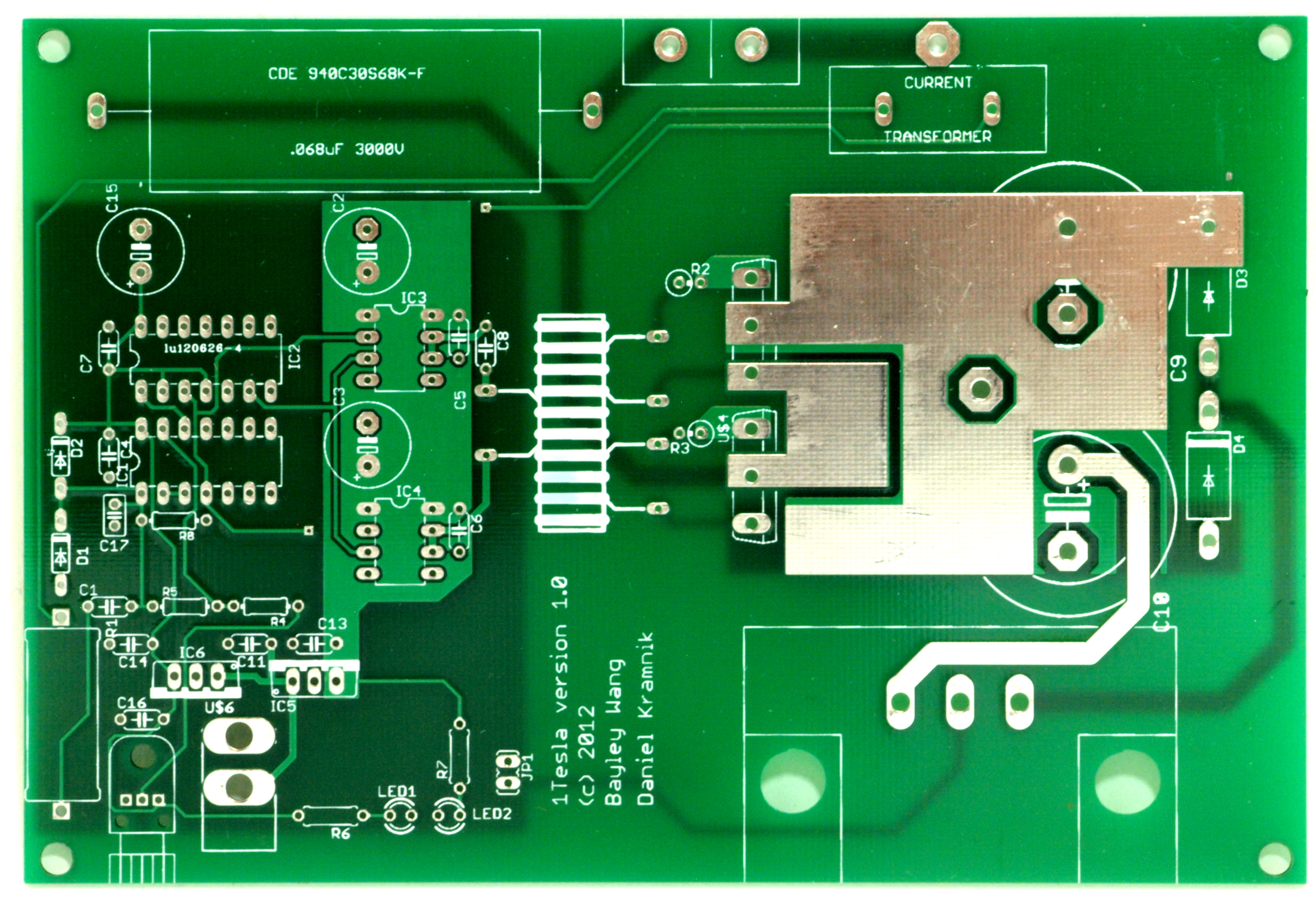

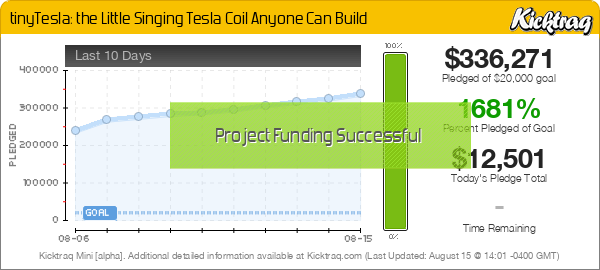

Shortly thereafter, the kinks in the MIDI code were finally ironed out, a low-pass filter was added at a key location, and the board was respun for commercial fabrication. The original idea was to send out for 50 boards from MyroPCB to take advantage of the price break, build a few coils, and peddle the rest on eBay in the form of simple kits to help recoup development costs.

At this point, I went on vacation to visit Heidi (who was interning at an accelerator in Germany). She pointed out that we would seem much more legit (and also be much more profitable) if we had a real web store and a good manual. Soon we had a nice website, and I wrote the first revision of the manual, which was done in LaTeX and looked like a math paper. Meanwhile, Kramnik added polyphony and figured out the limits of the driver design.

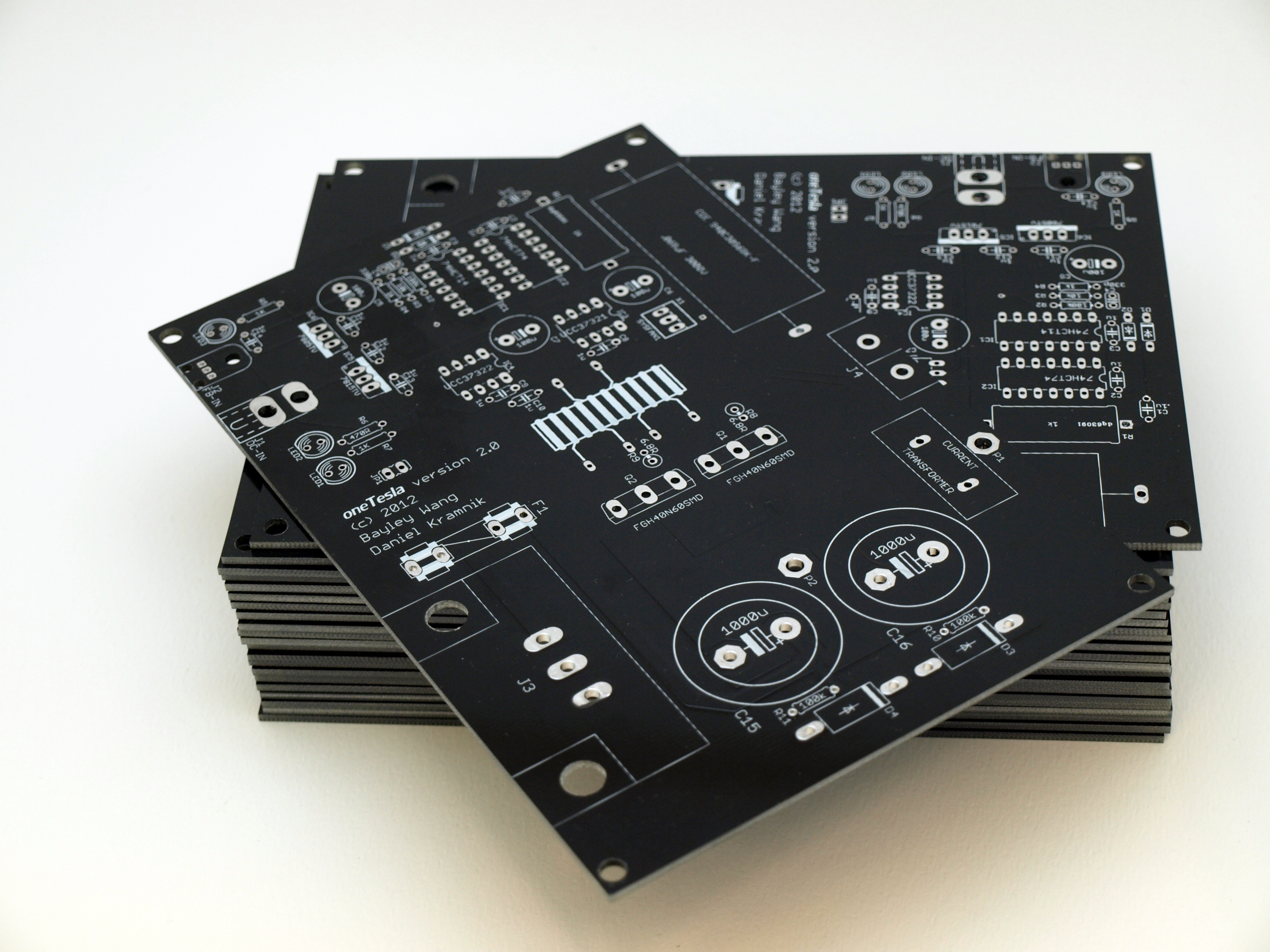

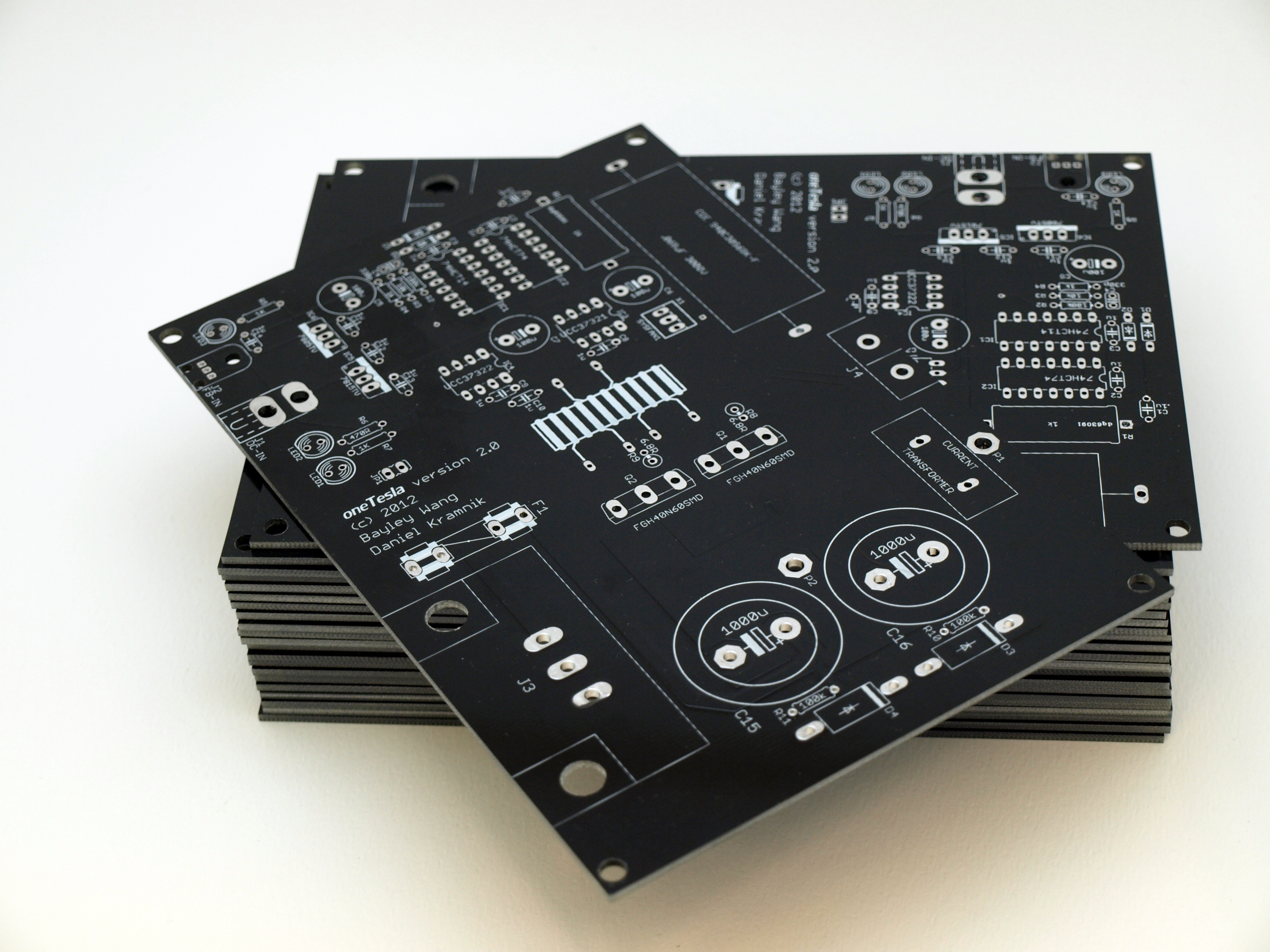

The manual was deemed stylistically unacceptable, so Heidi began re-writing it to read less like a technical paper and more like a manual. We also decided to scale up the operation and cater more towards the general "maker" community, as opposed to only experienced HV hobbyists. This turned into plans for a Kickstarter campaign (which is still in the works), and a massive and ongoing effort to streamline the supply chain, revamp the manual, improve safety, and simplify the assembly process. On the technical side of things, the board was respun with a few critical features (such as a fuse), the interrupter was improved, and we designed a nice acrylic case and primary supports for the coil.

So there you have it - the history of oneTesla. The design has come a long way from the day it was conceived; we've tripled our spark lengths and made the coil infinitely more reliable. It plays music, it's portable, it's consistent, and it even comes with a fancy lasercut case! At least internally, we can now go from zero to Tesla coil in a few hours. Hopefully, we can bring this simplicity and ease of assembly to you as well!

Why hello there, 2000 meters of fiber cable (and Heidi)

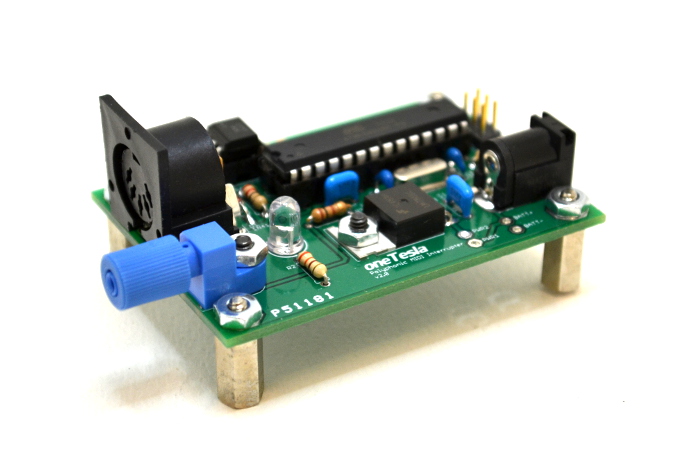

Why hello there, 2000 meters of fiber cable (and Heidi) The latest interrupter revision. Don't worry, the final revision will have a black board.

The latest interrupter revision. Don't worry, the final revision will have a black board.